— ABOUT US

DESIGNED ASSEMBLED IN ITALY

The T.G. MAC s.r.l. was founded in 1981 with the aim of building complete systems for glazing tiles for ceramic factory, and is located in the center of the ceramic district, has therefore enjoyed privileged conditions to develop a heritage of refined technology and specific knowledge. The T.G. MAC s.r.l. commits all its operational and economic energies to the continuous search for new technologies to improve the typology and production of ceramic tiles.

The T.G. MAC s.r.l. produces glazing lines complete of all accessories based on the customer’s needs and requests. Also complete with the latest generation electrical system that allows to check all system applications, all towing and consumption, equipped with screens information, cameras and sensors for production control that help operators to restore applications in the event of alarms or line stops, underlining the significant importance given to energy saving.

— COMPANY VIDEO

CONCEPT AND DESIGN

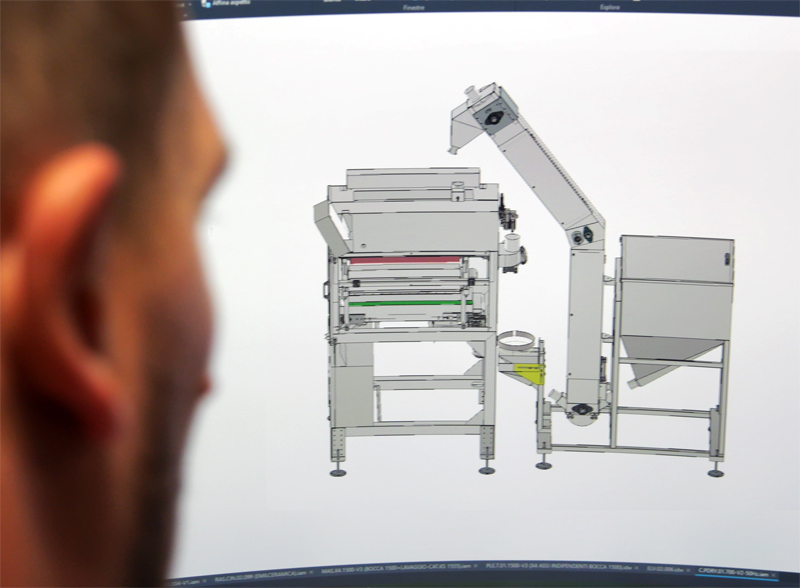

All the machines produced by T.G. MAC are designed on 3D CAD. Already at this stage it is possible to have feedback on the structures, dimensions and functioning.

Ideas and solutions for ceramic technologies, before being prototyped, are designed and tested virtually on design software. With these procedures the automations, machines and ceramic glazing lines designed by T.G. MAC acquire even more quality and reliability.

STAINLESS STEEL DEPARTMENT

Stainless steel is the favorite material par excellence in the construction of ceramic glazing machines. T.G. MAC has equipped itself with a specific department for stainless steel processing.

In this department the professional skills of the employees are specific and generally a lot of experience is required.

RAW MATERIAL

Nowadays almost no one stocks materials due to a question of costs. T.G. MAC, which produces ceramic glazing machines, always has good quantities of steel and various metals in stock almost, to have certain delivery times and also simpler and more direct control over costs.

LASER CUTTING

The quality of the machines starts from the carpentry, if the sheets are cut with

precision all the processes run smoothly. the cutting process is direct, from the drawing on the computer to the drawing on the machine to processing.

In T.G. MAC glazing machines steel sheet are an important component, using Trumpf Laser cutting the quality of precision is guaranteed.

SHEET METAL BENDING

In the sheet metal bending phase, the shape of the curves and edges is defined,

as in cutting, here too precision is fundamental for all subsequent assembly phases.

T.G. MAC for sheet metal bending – used in the construction of ceramic glazing machines – uses Trumpf machines where the quality of precision is guaranteed.

STAINLESS STEEL WELDING

Welding operations on stainless steel sheets are demanding and require specialized personnel with experience.

The quality of the welds defines the quality of the entire machines, especially in ceramic glazing machines where the seals of the glazes and liquids must be guaranteed.

MACHINES ASSEMBLY

The assembly phase is very demanding, the machine must be built as if it were already in the ceramic department. Very often in this phase it is possible to improve the practical and operational aspects as well as verify the perfect correspondence of the result to the initial project.

In every machine, in the assembly phase, in addition to the carpentry, various elements such as motors, belts, sensors, etc. are joined together… all managed by intelligent software that learns and improves the functionality.

MACHINES PRODUCED IN SHIPMENT

All machines sold by T.G. The MAC are assembled in the company and the movement mechanisms are tested. Once this phase is completed, they are prepared to be shipped to the customer where they will be integrated into the

ceramic lines.

Glazing machines have delicate ceramic parts and it is important that they are

prepared with the right protections to reach the recipients intact.

SPARE PARTS SERVICE

T.G. MAC is aware of the importance of productivity in the ceramic industry, to this end it has set up a spare parts service which quickly processes requests, retrieves the piece from the warehouse and sends it for shipment.

This service ensures that even older ceramic glazing machines can continue to do the job without interruption for the customer.